该仪器可以测定从常温到高温的维氏硬度,最适合用来验明耐热金属材料、陶瓷制品等新材料的高温硬度。

高温炉:高温炉是与轴部连接和可观察试料的旋转装置,是带有试样加热装置及试样加热部分的移动装置的密封性加热室。

加热环境:首先使高温炉内加热到所需温度,然后测定硬度。

试验方法:高温炉的轴部是在保持炉内密封的同时使炉子自由升降,可以从炉外向炉内试样施加试验力。而且,从炉外施加的试验力和试验力的控制取决于维氏硬度计。

可选模块:高温金相测试系统及高温原位拉伸及压缩系统

试验力加卸载与试样压痕测试的转换:将安装于高温炉上部旋转板上的压头对准试样位置,进行加载或卸载,然后将观察窗旋转至试料位置,由CCD进行压痕对角线的测定及读取维氏硬度值。

1、压痕制造系统:

这是一个硬度计完整系统中的核心部分,主要涉及力学性能测试,无论加载时间及保载时间都需要精确控制。

该仪器采用闭环伺服传感器加载原理,并用C字形结构增强仪器刚性,并用有限的技术参数综合分析技术去配合温度及测试力之间的影响。

该仪器采用力值适时补进机构,首先杠杆与砝码在加载卸载之间无猛烈冲击,同时具有过载保护功能。力值之间转化可以实现自动转换,非常便利,并且加载速度可调。

该仪器采用特殊测头在高温炉内进行高温维氏,同时压痕测量亦在同一环境进行。

可选高温原位拉伸压缩测试系统,进行原位拉伸压缩及压痕复合测试。

3、压痕测试系统:

由计算机控制的CCD图像处理系统实现了人机对话,他将压痕通过专用硬度测试软件采集到计算机,由计算机进行压痕图像处理,对角线的测量、硬度值的计算、显示、数据分析统计,并可以以报告形式打印,测试数据可以以文件方式导出。

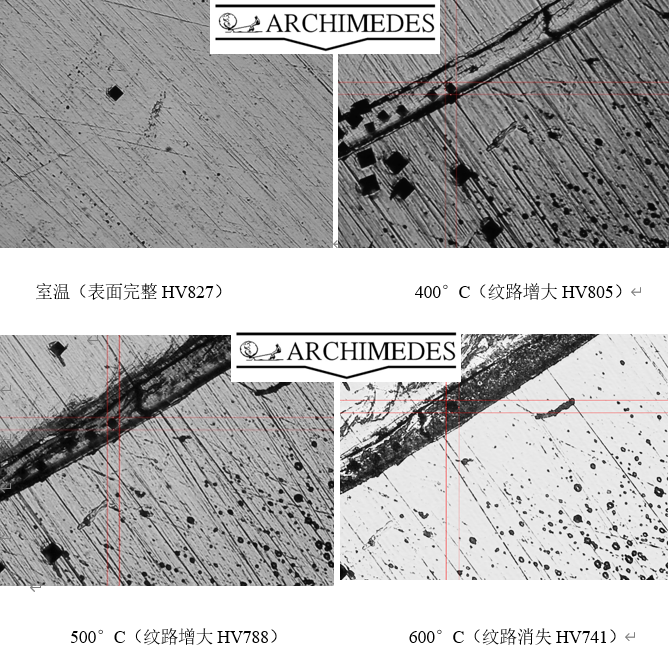

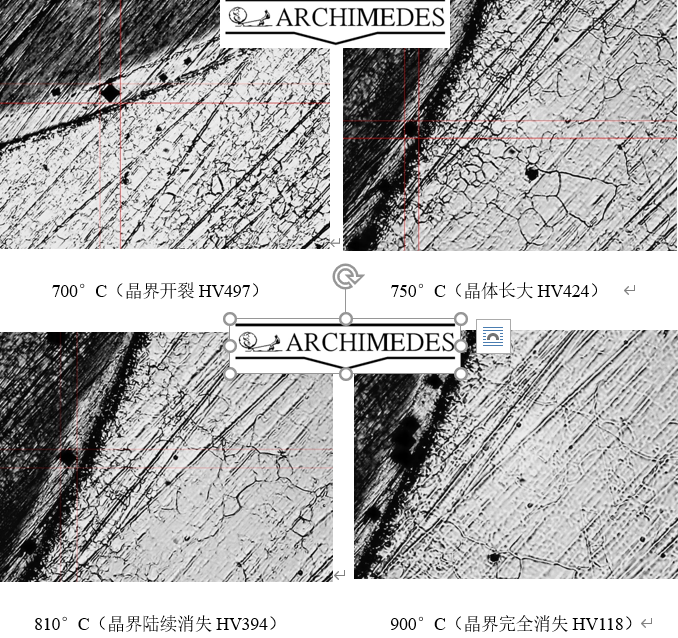

不同温度下的高温硬度

高温金相

高温原位拉伸及压缩(应力应变曲线)

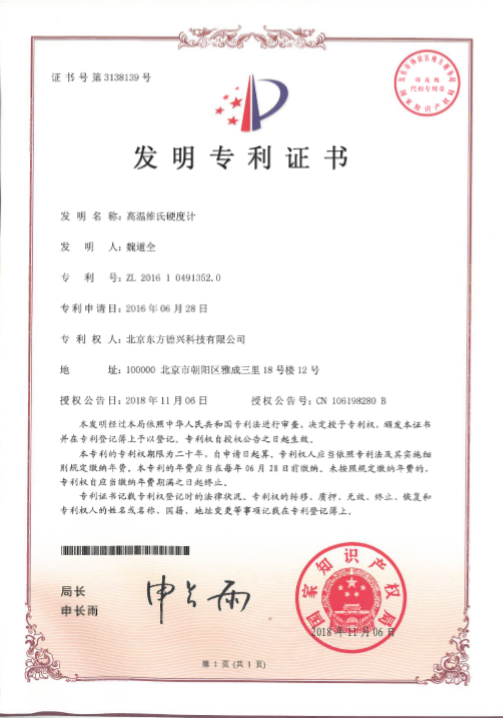

发明专利(该设备由我公司经过十年技术升级,功能非常强大,可以原位测试高温下的硬度,金相及强度等技术参数)

专利点(请勿侵犯专利,违者必究):

1.采用手套箱做纯氩气气室保护,隔离试样高温氧化。

2.激光加热,提高加热温度及图像清晰度。

3.光学升级,排除干扰光源,捕捉压痕清晰图像。

4.原位测试,在高温下测试高温图像,测试拉伸机压缩试样,提升精准度。

5.水冷及隔热保护措施,防止镜头及设备高温烧毁。